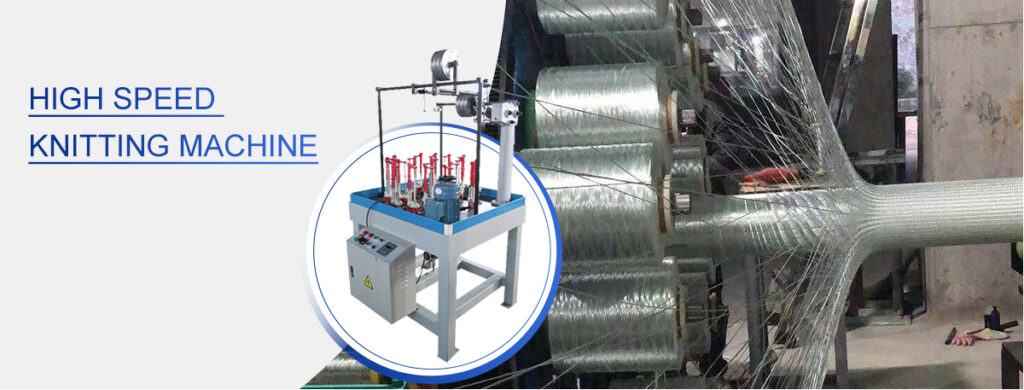

Do you understand the weaving performance characteristics of high-speed knitting machines? Let’s learn more about it.

- High-quality parts and effective intermediaries make the machine run longer and have a longer service life.

- Humanized design, safe and simple operation, direct and convenient daily maintenance of equipment.

- It is not easy to break or damage the surface of the raw material during weaving. After weaving, it is of course of high quality. If there is a core-spun product, automatic feeding can be used, and it can be properly sent out regardless of the size of the core.

- The hanging-type industrial ceramic eye (aluminum oxide) is installed at the exit point of the spindle drop group to replace the hole-breaking work. The reasonable structure of the drop spindle makes it easier to change the bobbin and optimize the elasticity.

- The fully automatic yarn-breaking and power-off equipment of this machine is convenient and accurate. When the core is used or disconnected, the machine will automatically stop running, so the machine can be safely operated without human operation, so as to increase production and control costs.

- The motor adopts frequency conversion control and infinitely variable speed, which is easy to control the speed ratio and can be maintained overweight.

- Standardized parts supplement and after-sales service guarantee will bring a strong guarantee for the normal operation of your machine.

- High-quality, high-speed operation and high quality will give you more indoor space.

The main application of high-speed braiding machine: It is mainly used for weaving various circular or flat inelastic and elastic ropes, mainly weaving various ropes, shoe ropes, elastic ropes, decorative belts, high tension belts, fishing net lines, fishing lines, trailer ropes, ship rope, curtain cloth rope, cable, chemical fiber, and other high-quality products.

Features of high-speed braiding machine:

- Frequency conversion step-less speed regulation, flexible parking at yarn breakage, synchronous satin feeding, control of satin yarn breakage, low energy consumption, and high output.

- The surface of the machine has been seasoned to improve wear resistance, and the key parts have been heat-treated and ultra-finishing, making them durable.

- The equipment has high operating performance, easy maintenance, and convenient use.

- The total area is small and easy to use.

- The operation of the control panel of the electrical box is easy to understand.

- Application cables: stainless steel wires, copper wires, tinned wires, silk-covered wires, nickel-plated wires, braided wires, carbon fiber materials, pure cotton yarn materials, etc.