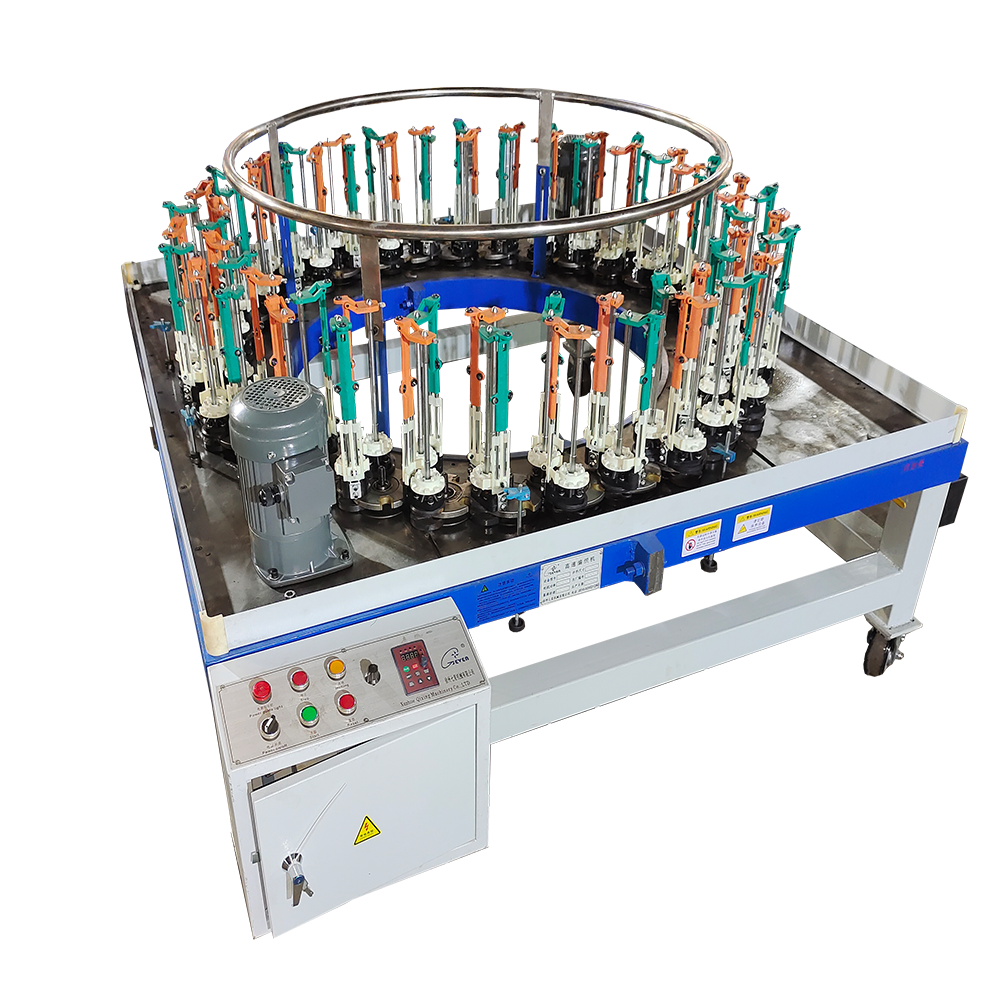

The high-speed knitting machine is controlled by a computer motor, and also has the following safe operation modes;

一、Stop when the thread breaks: During the whole process of knitting, when the wool thread breaks suddenly, the engine will immediately stop the operation mechanism,

二、Automatic shutdown of load: During the knitting process, if the yarn is coiled, bent, damaged, etc., the operation is blocked. When the load is too heavy, it will automatically shut down and automatically memorize the number of knitting pieces. Shut down, and automatically memorize the number of knitting.

Needle bed movement: The high-speed cable and wire knitting machine is controlled by a servo motor and a ball screw device. The needle movement range is 1/4-8 needles, with a precise adjustment function.

High-speed knitting machine needle reading system software: Use an excellent servo motor to read needles.

Triangular system software: It has five functions knitting, transfer, tuck, non-knitting, and stitching. When transferring, “front-turning” and “back-turning-front” will not be limited by the engine’s operating position.

High-speed knitting machine density triangle: stepping motor control, 26-segment density selection, 15 density groups, subdivided technology, adjustable range (0-255), can accurately control the density of sugar-coated tablets.

High-speed knitting machine cloth winding system: computer program command, stepping motor control, infinitely variable speed, and precise adjustment function.

High-speed knitting machine characteristics.

- High-quality parts and effective organization make this equipment run more smoothly and last longer.

- Personalized design, simple operation and protection, simple and convenient maintenance of equipment.

- It is not easy to break the thread or damage the surface of the material during weaving. After weaving, of course, it has a higher quality. If there is a product with a core, automatic feeding can be used, and the usage amount can be properly delivered regardless of whether the core is large or small.

- The hanging-in industrial-grade porcelain eye (aluminum oxide) is installed at the outlet point of the Yanluo spindle group to replace the hole-breaking work. The effective structure of the Yanluo spindle makes it easier to replace the bobbin and adjust the elasticity.

- The automatic yarn break stop device of this equipment is convenient and accurate. When the core is used up or the line is broken, the equipment will automatically stop running, so the equipment can be operated intimately without human control, so as to increase production and control costs.

- The motor adopts frequency conversion control, infinitely variable speed, easy control of the speed ratio, and can be maintained under overload.