A braiding machine is an important piece of equipment in the textile industry, capable of interweaving materials such as yarn, webbing, or cords together to make a variety of different textiles. As market demand continues to increase, more and more people are paying attention to the cost-effectiveness of braiding machines, hoping to find a manufacturer that can provide high-quality machines. This article will introduce how to find a cost-effective braiding machine manufacturer.

一、Brand reputation and history

First of all, brand reputation and history are important indicators for judging the cost performance of a braiding machine manufacturer. An excellent brand history can show a company’s competitive strength in the market and prove its maturity in technology, services, etc. Generally speaking, brands with a longer history and good reputation are more trustworthy, because these brands usually operate stably for a long time and have more stable product quality. Emerging brands should pay more attention to the strength and production capacity of manufacturers and weigh their cost performance.

二、Machine quality

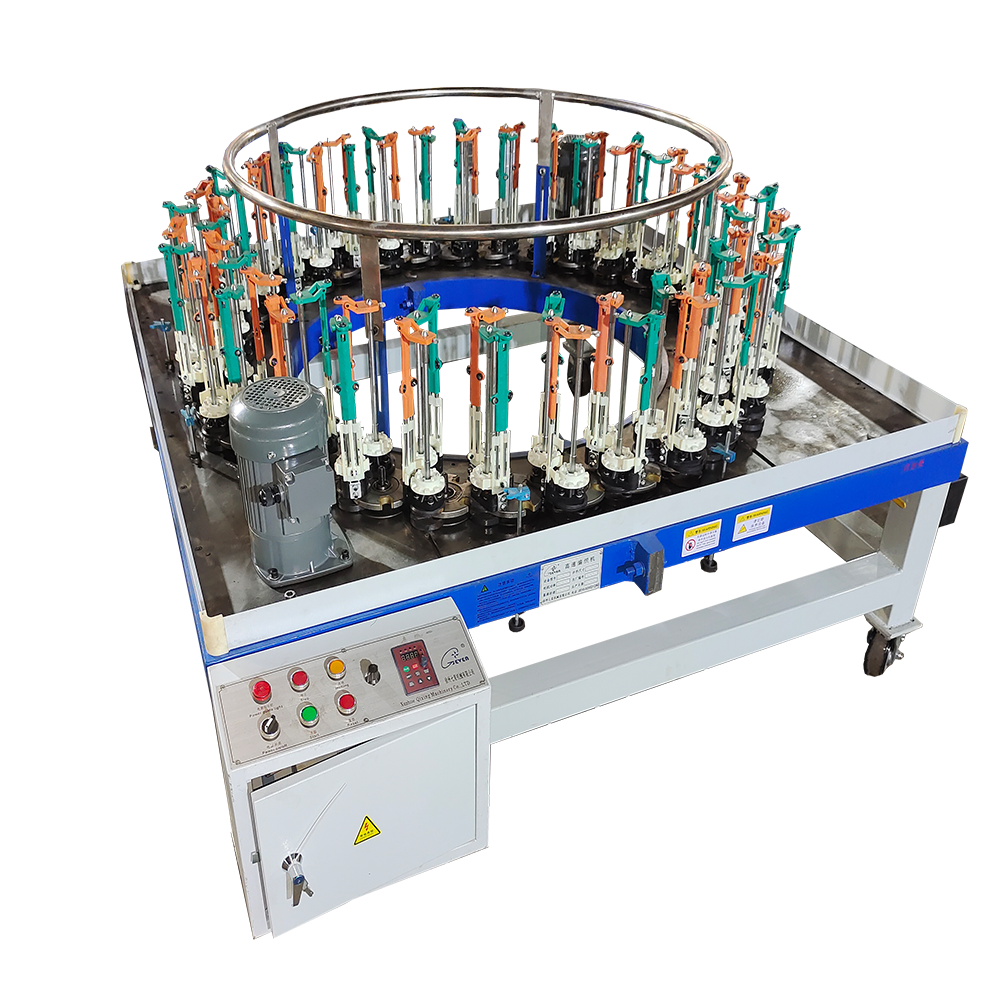

Secondly, the quality of the braiding machine is also an important factor affecting its cost performance. Knitting machines deeply apply machine control technology, and the coordination between mechanical performance electrical performance, and the stability of the system is crucial. Therefore, the requirements for braiding machines are very high, and the accuracy of spare parts and the quality of materials are very high. High-quality materials must be selected and a professional production environment must be used to create high-precision machines and ensure their long-term stable operation.

三、After-sales services

Thirdly, after-sales service is also an important factor in judging the cost-effectiveness of braiding machine manufacturers. Xuzhou Qixing Machinery Co., Ltd.’s braiding machine after-sales services include installation and commissioning, training, maintenance, and repair. In order to ensure the long-term stable operation of the machine, when purchasing a braiding machine, you need to consider whether the after-sales service is perfect, whether the technicians are professional, and whether the problems are solved in a timely manner to ensure the continuity of the customer’s business. When choosing a braiding machine manufacturer, you need to comprehensively consider these factors and try your best to choose a manufacturer with excellent after-sales service.

四、Affordable

Finally, price is also an important factor in considering the cost-effectiveness of a braiding machine. In the domestic market, prices vary greatly, and there are also certain price differences between different brands and models of braiding machines. Consumers can understand the market conditions and price levels of various brands of equipment before choosing a braiding machine, and make comparisons to choose manufacturers and products with higher price ratios.

In short, when purchasing a braiding machine, you need to comprehensively consider the above factors, evaluate the strength of the manufacturer and the cost-effectiveness of the braiding machine, compare and select, and then select a high-quality machine that suits you to improve the efficiency and competitiveness of your company.