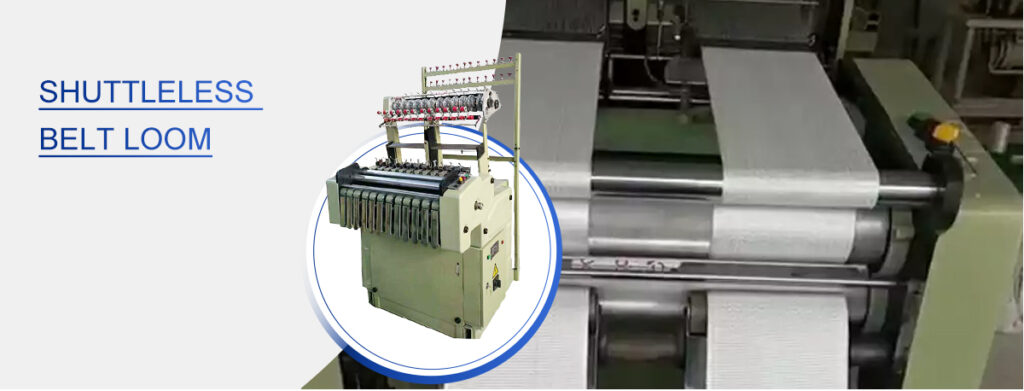

The weaving machine uses polypropylene and polyethylene plastic wire drawing machine to weave into agility, which is used for flexible container bags as camisoles, loop belts, and reinforcement belts. What are the technical parameters of the weaving machine? Let’s find out together.

- Dimensions of the loom (length*width*height): 7000*1800*2120mm.

- Main rated power: 1.5kw.

- Production volume of ribbon loom: (100-150)*2m/min.

- Relative density of warps: 1.8-5/cm.

- Woven label width: ≤100mm.

- Reed width: 110mm.

- The number of weaving labels for the loom: 2.

The structure of the ribbon loom is reliable and compact, and the thermal movement of molecules is flexible. The performance parameters mainly include the above aspects. According to the above-detailed introduction, I hope to increase everyone’s understanding of the ribbon loom, and it can be of some help to everyone.

The ribbon loom is mainly used for weaving all kinds of ropes, shoe ropes, elastic ropes, decorative belts, high-tension belts, fishing nets, fishing lines, etc. It is suitable for weaving various rings or flat non-elastic and elastic ropes Belt, let’s take a look at the operation steps of the ribbon loom:

Before the operation of the ribbon loom, full preparations must be made, such as yarn hooks, pens, measuring tape rulers, yarn scissors, etc. must be prepared.

Operation steps of ribbon loom:

- The emerald green button of the ribbon loom is “free ride”, press the slow button to observe the edge, and the weft yarn transmission can drive fast if there is no abnormality in the weft yarn transmission.

- The amber button is down for “slow”.

- The red button of the ribbon loom is “shut down”, which is used to change the weft yarn, and side yarn, solve the disordered yarn, pilling and the surface quality of the nylon conveyor belt is not up to standard.

The cloth cutting machine is used in the fields of clothing accessories cutting, hollowing out and carving, etc., and has obvious advantages. Below we will give a detailed explanation of the products of the cloth-cutting machine so that everyone can easily understand:

- The cloth-cutting machine is equipped with a safety device, which is safe and convenient to use.

- The cloth-cutting machine rotates laser cutting, and the design of three cutter heads makes the cutting speed faster and neater.

- Strong and sturdy.

- The feed rate is adjustable and the slitting width is adjustable.

- Unique design scheme, there is a model that is very suitable for cutting large materials.

The cut of the cloth cutting machine is smooth without loose edges, with no deformation, consistent, and accurate in size; at the same time, it can be cut in two layers to make any complicated shape; high efficiency, low cost, and better effect. We sincerely invite you to discuss and purchase.