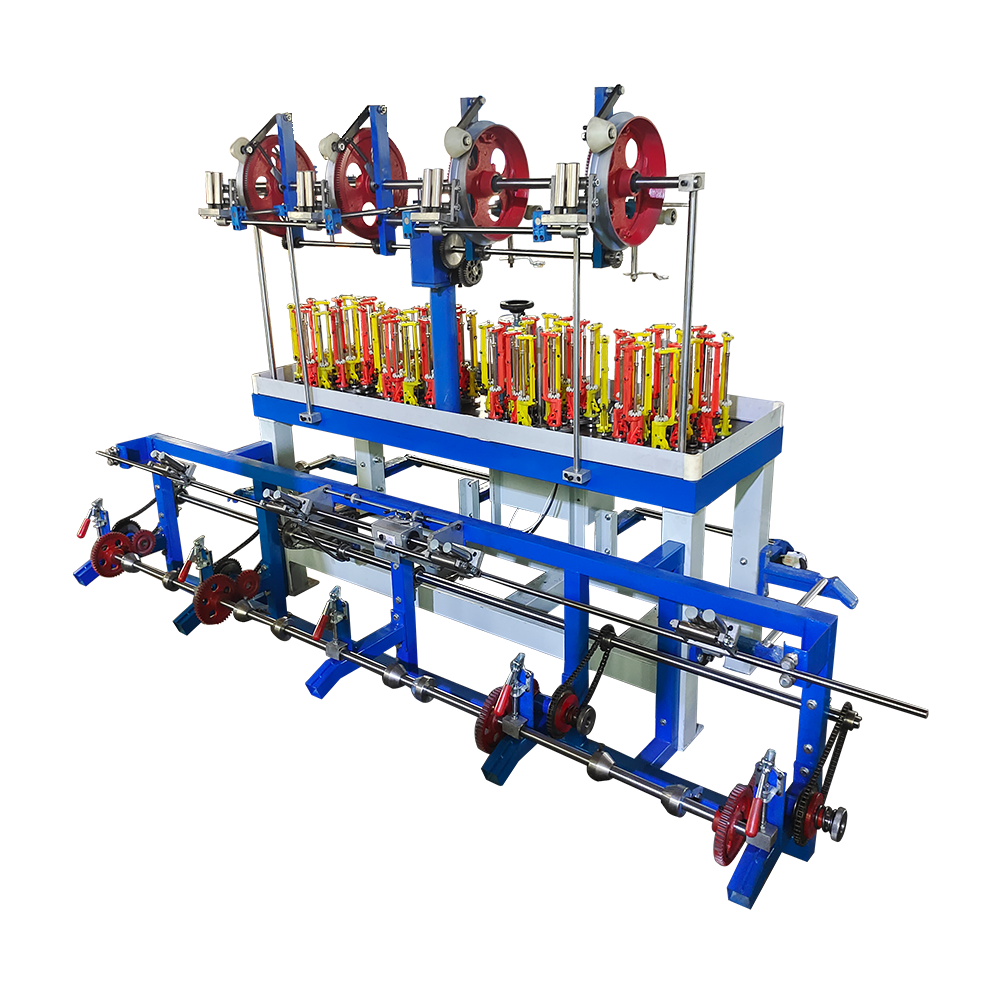

When the high-speed braiding machine is manufactured, the equipment is in a running state for a long time, and the static deformation and dynamic deformation of the equipment will change all the time, which will gradually increase the partial deviation and system deviation of the parts that have been tightened or connected. Eventually, the spatial relative position of some parts is moved, and the processing distance changes, resulting in changes in the processing state and reduced product quality. Regardless of whether the device is running or not, its static data form always exists. After operation, the dynamic deformation is improved. These two deformations deform the threads of the screw nut and the screw rod, causing the connection to loosen gradually, the washer to become soft after being squeezed, and the elasticity of the self-locking nut to decrease.

Countermeasures for tightening and maintenance of high-speed braiding machine fasteners:

- Use safety inspections to check whether the key process components and tightening joints of each piece of equipment are loose, and tighten loose parts in time.

- Purchase standard tightening joints from designated factories in my country and build a safety inspection team with inspection as the key.

- Unify the tightening procedures of fasteners to minimize under-tightening or over-tightening, which may cause potential failures or reduce the service life of tightened parts.

Establishing an inspection-centered inspection system is to better maintain the performance of the equipment and inspect the equipment in accordance with specifications so that abnormal conditions of the equipment can be detected early. Creating an inspection-centered inspection system is to do a good job in maintenance. the main ways. The so-called maintenance refers to the inspection and inspection of key parts and items of equipment. Conditional maintenance always highlights the condition, and every part of the equipment in daily operation is inspected every day. Consistent tightening operation methods of fasteners avoid over-tightening or under-tightening, which may cause potential problems or increase the service life of the entire tightening unit.

These two deformations deform the fingerprints of the anchor bolts and screw rods, causing the coordination to gradually loosen, the bottom pad to become soft after being squeezed, and the spring seal ring to land elastically.