There are all kinds of high-speed braiding machines on the market. As an ordinary customer, it is a crucial part of the purchase of braided tubes to distinguish the quality of braided tubes. The braided pipe is basically manufactured by the braiding machine, and processed by the assembly machine, crimping machine, and other auxiliary equipment. Therefore, in terms of quality evaluation, the following fields can be used for analysis.

一、The aramid fiber weaving machine checks the glossiness of the surface to see if there are blisters, protrusions, sponges, trachoma, etc.

二、Composite knitting machines bend the surface to see if there are any visible cracks.

三、The three-dimensional knitting machine checks whether the weaving and raising layers are sorted standardly, and whether the closeness and sparseness are consistent.

四、Look at the cross-section, whether the inner hole and the steel wire layer are round or not, and whether the inner rubber layer and outer rubber layer are uniform in thickness.

五、Cut the inner glue and outer glue with your fingernails to see the firmness and level.

六、Look at the raw materials, and smell the smell of the inner and outer rubber with your nose to see if it is pungent.

七、Look at the hot stamping of the pipeline, whether there are trademarks, company names, and other information.

八、For the finished product tube, you need to pull the following connecting parts to see if the connection is firm.

九、If the conditions are acceptable, carry out the following pressure test to see if there is water leakage.

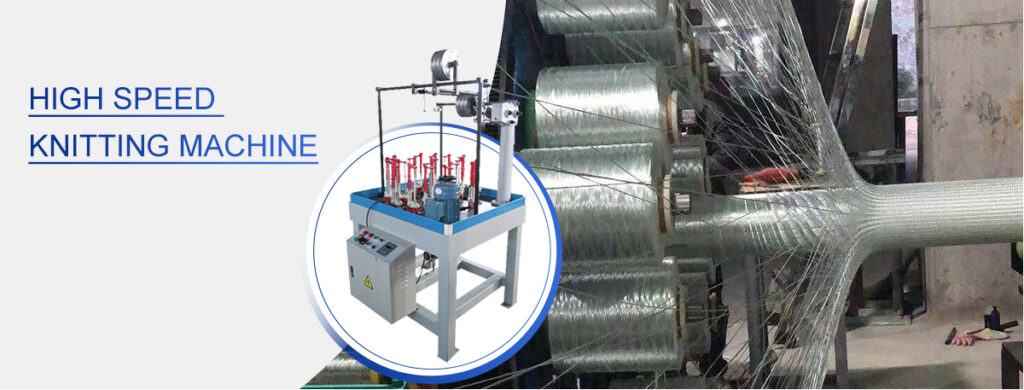

Some components of the high-speed braiding machine, such as the spindle support frame, sliding seat, etc., must ensure the correct distance between the sliding seat and the lower spindle braiding line after maintenance and disassembly or when adjusting new parts and reinstalling. It is suggested to place a sliding frame and the subordinate upper spindle to run on the sliding wheel so that when the braided wire of the lower anchor is led from the swing rod to the weaving point, it will not be entangled or disconnected by the sliding frame.

During rough adjustment, place the spindles on the two adjacent outer spindle support frames, guide the braiding wires to the braiding point according to the swing bar, and stack them tightly. When the carbon fiber braiding machine braiding wire enters or exits from the slot on the sliding wheel rail, the distance from it to the edge of the upper spindle carriage must be almost the same. The adjustment of the distance can be accomplished by switching the gear frame forward or backward by one or more gears.

If you cannot adjust the distance accurately by moving one tooth, you can adjust according to the following steps: Loosen the five fixing screws on the inner gear, because the buried hole is elliptical, and the sliding frame can be realized by moving the inner gear Adjust and tighten the screws after adjusting in time. Place the other sliding frames evenly on the sliding ring rail. If the swing height of the braided wire is different after the new swing rod is installed, it should be adjusted until all the swing rods have the same endpoint.