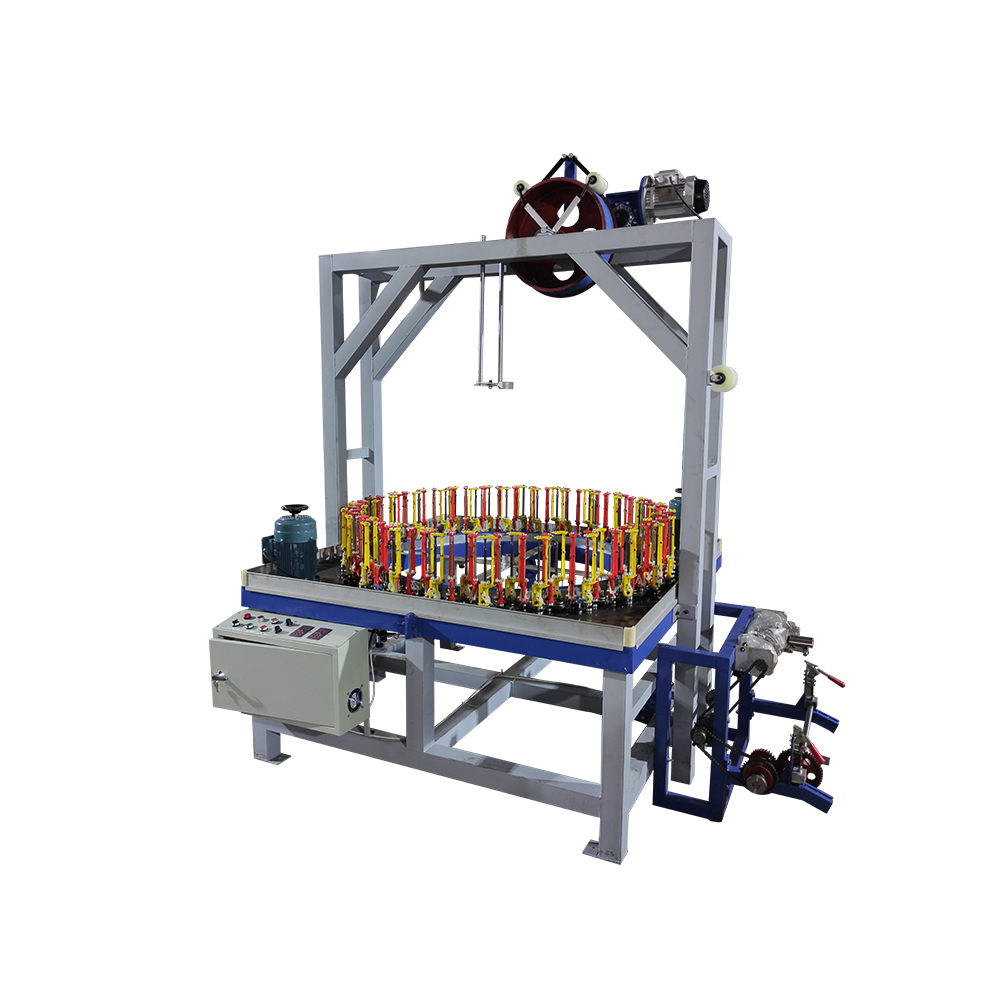

How to make the high-speed knitting machine run safely? Let’s learn more about it.

- The motor adopts frequency conversion control, and the stepless variable speed is easy to control the speed ratio and can be overweight and maintained.

- Standardized parts supplement and after-sales service guarantee also bring a strong guarantee for the normal operation of your knitting machine.

- At the exit point of the trolley spindle group, a hanging-type industrial porcelain eye (alumina) is installed to replace the hole-breaking work. The reasonable structure of the trolley spindle makes it easier to change the bobbin and optimize the elasticity.

- The fully automatic yarn-breaking and power-off equipment of the high-speed knitting machine is convenient and accurate. When the core is used or disconnected, the machine will automatically stop running. Therefore, the machine can be safely operated without any actual operation, so as to increase production and control costs.

- High-quality parts and effective intermediaries make the machine run longer and have a longer service life.

- The humanized design is easy to operate, and the daily maintenance of the equipment is convenient and convenient.

- It is not easy to break or damage the surface of the raw material during weaving. Of course, there are relatively high-quality products after the knitting machine. If there is a product with a core, automatic feeding can be used to send out the appropriate amount regardless of whether the core is large or small.

Conditions for the safe operation of high-speed braiding machines:

- High-quality parts and an effective intermediary mechanism make the knitting machine run longer and have a longer service life.

- The humanized design is easy to operate, and the daily maintenance of the knitting machine equipment is convenient and convenient.

- It is not easy to break or damage the surface of the raw material during weaving. Of course, there are relatively high-quality products after the knitting machine. If there is a product with a core, automatic feeding can be used to send out the appropriate amount regardless of whether the core is large or small.

- The motor of the knitting machine adopts frequency conversion control, and the stepless variable speed is easy to control the speed ratio and can be overweight and maintained.

- Standardized parts supplement and after-sales service guarantee also bring a strong guarantee for the normal operation of your machine.

- At the exit point of the trolley spindle group, a hanging-type industrial porcelain eye (alumina) is installed to replace the hole-breaking work. The reasonable structure of the trolley spindle makes it easier to change the bobbin and optimize the elasticity.

- The fully automatic yarn-breaking and power-off device of the knitting machine is convenient and accurate. When the core is used or disconnected, the machine will automatically stop running. Therefore, the machine can be safely operated without any actual operation, so as to increase production and control costs.