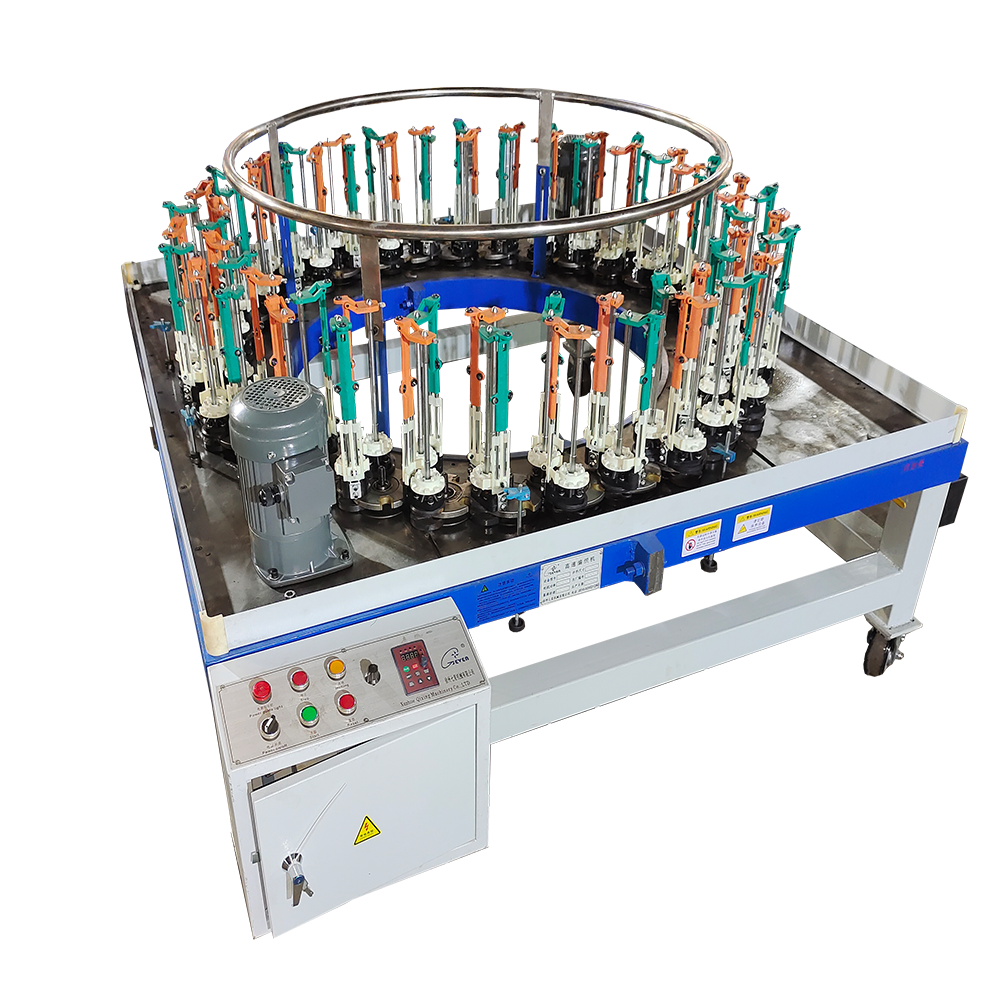

High-speed braiding machine appearance inspection:

Carry out visual inspection, and the inspection items are mainly based on product conditions such as smooth and shiny surface, uniform gloss, no core deviation, no mechanical damage, no pressure deviation, and no visible dirt, bubbles, sand holes, obvious of granules, round bamboo shapes, hemp flowers, etc. The electrical conductor and the insulator or the sheath and the insulator are not allowed to adhere. The braid should be even and there should be no obvious problems such as yarn leakage, yarn running, yarn breakage, etc. It is stipulated that conductors should not be oxidized, and tin-plated conductors should not have tin leakage or tin bumps.

High-speed braiding machine product specifications and inspection of knitting parameters include:

I am braiding machine product diameter, thickness, pitch, and product weaving density. There are two ways to measure the weaving density of products. 1. Measurement method: 1. Use a vernier caliper to measure the diameter D before weaving. 2. To measure the knitting pitch h, use the paper tape method to measure the signature pen wear mark. 3. Half of the amount of knitting machine spindles is the number of strands in one pitch. 4 The number of wires on each spindle n5 The outer diameter d of the iron wire is measured with a vernier caliper. 6. Calculate the braiding angle a=arctg(h(3.14(D+t)t) – braiding thickness, and the metal wire t is the diameter of a single wire. 7. Calculate the single-sided covering of the braiding layer p=and/(hcosa8). The total penetration rate of the braided layer P = (2p-p2) * 100 (%) 2. Weighing method: The weight of the braided layer is compared with the weight of the same diameter pipe made of the same type of iron wire.

How to solve the quality problems of braiding machine products of Xuzhou Qixing Machinery Co., Ltd.:

- The weaving density does not meet the requirements, the number of spindles, the number and diameter of each spindle, the weaving pitch, and the weaving angle should be consistent with each other.

- If the density of the braided layer is uneven, the torsion spring that controls the supporting force should be carefully adjusted to keep it relatively even and moderate, so as to achieve the purpose of uniform braiding density.

- If the braiding pitch is uneven, you should first check whether the number of turns of the cable on the brake wheel meets the requirements, because it is easy to cause the cable to roll when the number of turns is small. If the number of turns of the cable on the brake wheel is increased appropriately, Increase the friction resistance to prevent the cable from rolling and ensure a uniform braiding pitch. Once again, you should check whether the spindle rotation speed and the traction belt angular speed match smoothly.