The interface installation of high-speed braiding machine plastic hoses is welded in many areas. This welded interface method is very traditional and has been gradually replaced. At present, in the market, welding machines have been gradually replaced by crimping machines for connector installation.

Xuzhou Qixing Machinery Co., Ltd. introduces the crimping machine relative welding machine with outstanding advantages:

1、Security advantages:

The welding machine needs to be connected to acetylene gas O2, and the welding process will also cause high temperature and fever, which is very prone to safety accidents; while the crimping machine only has one hydraulic hose device, which greatly improves the safety factor.

2、Stable quality:

Whether it is manual welding or machine welding, leakage of welding will occur, which will cause problems such as water seepage in the plastic hose of the braiding machine. However, the crimping machine is formed in one go, so there is no need to worry about this problem at all.

3、Work efficiency:

The welding method has a whole process from high temperature to ultra-low temperature and rotary electric welding. The efficiency is undoubtedly not as high as the one-time forming of the crimping machine.

4、Labor costs:

Whether it is manual welding or machine welding, the requirements for the professional skills and proficiency of welding operators are very high. If the technicians pass the customs clearance, quality and safety accidents are likely to occur; and the operation of the crimping machine, even a beginner can get started by watching it for only ten minutes.

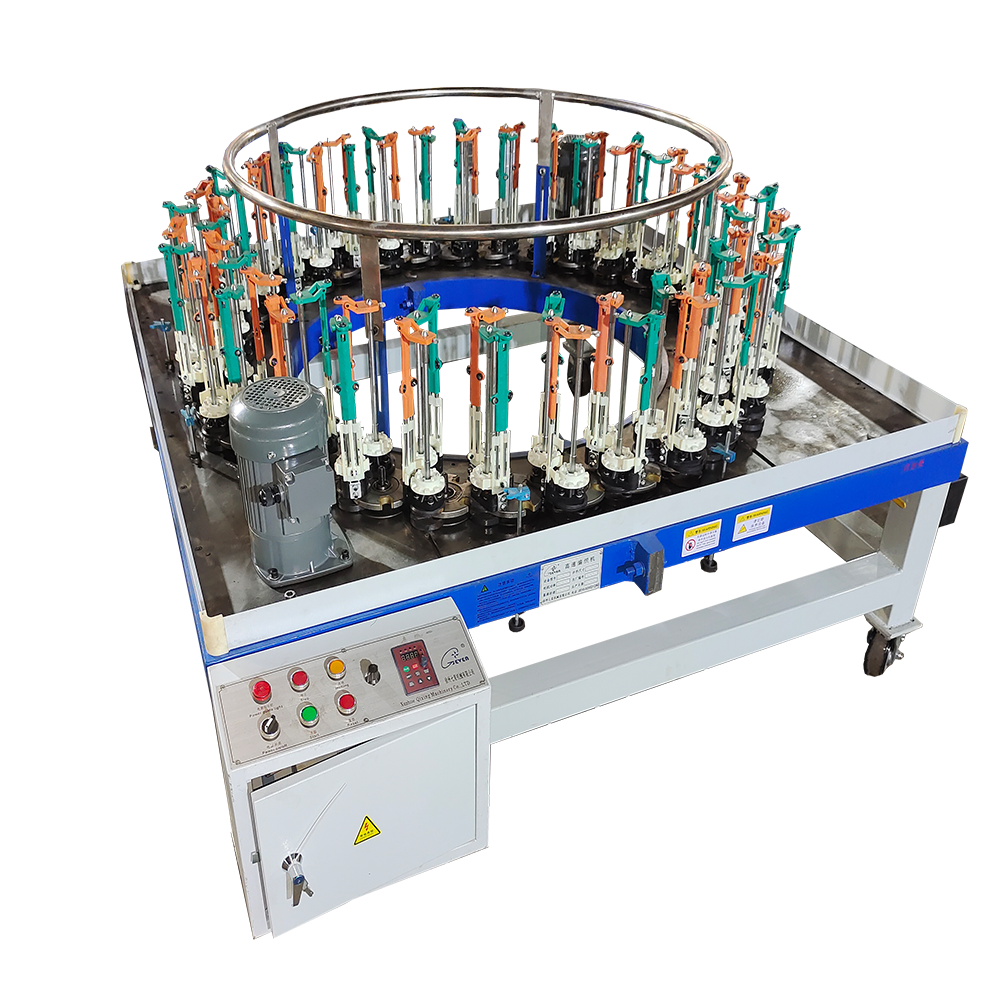

The crimping machine is an important auxiliary equipment for high-speed wire braiding. It can also efficiently solve the installation and sealing problem of braided wire connectors. The production of braided wires also has obvious advantages in the market:

1、There are many suitable die forgings:

This crimping machine is mainly tailor-made for the crimping work of braided wires and can handle a variety of braided wires for crimping operations. In comparison, it is newer and better than similar crimping machines from other manufacturers.

2、Convenient supporting facilities:

We have been committed to the production of knitting machines for 20 years and have sufficient production capacity in the field of wire knitting; all the auxiliary equipment of the knitting machines are tailor-made and are fully equipped with the knitting products that satisfy customers, eliminating the need for various specifications and models. Production failures caused by factors such as mismatch can help users quickly and effectively enter the production state.

3、More systematic:

China Braiding Machine National Standards Development Co., Ltd. is one of the best in my country in the production of braiding machines and braided wires. All braiding machines, including crimping machines and other braiding machines, are extremely systematic.